The Substrate Database was developed by the ILRC Committee of the Technical/Scientific Working Group for Fire and Explosives. The Substrate Database is a compilation of characterization data from materials which may produce interfering products in fire debris. The Substrate Database is a tool designed to assist forensic analysts conducting fire debris analysis.

How to import the data file into Chemstation

After you download and save the common data format (CDF) file, import the file into Chemstation with the import function.

Best Practices Guide

The Ignitable Liquids Reference Collection committee has prepared a guide so users of the database are aware of the considerations and limitations of the sample data contained in the database. The guide describes sample preparation and defines database limitations.

User comments are welcomed by the ILRC committee, please contact the ILRC committee chair.

Definitions and Search Tips

Material Use refers to the intended use of the product. Material Use Sub-class further specifies the intended use. The use must first select a Material Use and then select from a list of Material Use Sub-class. For example: to view records of carpet products, select Flooring and then Carpet.

There are ten related records for most substrate materials. Unburned, and then three burning methods each with three time intervals. Method refers to the burning method. For each method there is a time interval (Time Intervals).

Ignitable Liquid Residue Present refers to any combustion or decomposition products that are an ignitable liquids or resemble one.

Material Composition refers to the type of material of the major constituent of the substrate material.

Sample Preparation

Substrate samples for records MRN 1 to 216 were prepared using a sample size of 6 cm squared. There are two records for each substrate: unburned and burned by the 2 minute modified destructive distillation method. The burned method is described below.

Substrate samples for records beginning with MRN 220 were prepared using a sample size of approximately 16 cm squared or 1.5 grams. Each substrate is burned by a modified destructive distillation method (MDDM), a direct method (DH), and an indirect method (IH). The substrate samples were burned at three different time intervals for each burning method. Including the unburned sample, each substrate has 10 related records.

Modified Destructive Distillation Method

Substrates are placed into an unlined quart metal paint can with the substrate surface defined as the part of the substrate most commonly exposed to a heat source, laying upon the bottom of the can. For example, a carpet sample is positioned so the tufted or woven textile side is in contact with the bottom of the can. Nine holes of approximately 1 cm in diameter are punched into the can lid and then placed on the can without sealing. Heat is applied with a propane torch so the tip of the torch is 4 cm from the bottom of the can and the flame is centered. Once smoke appears from the top of the can, the time interval begins. A sample is prepared for each of the three times intervals: 1, 2, and 5 minutes. At the end of the time interval, the propane torch is removed. The punctured lid is replaced with an intact lid and the can is cooled to room temperature.

Direct Heat Method

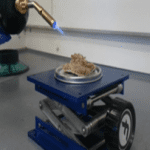

Substrates were placed onto an upside down lid with the substrate surface most commonly exposed to a heat source, facing upward. For example, a carpet sample is positioned so the tufted or woven textile side faces upward towards the propane torch. The torch flame is positioned at a 75 degree angle and 4 cm from the substrate sample. The time interval begins immediately. A sample is prepared for each of the three time intervals: 1, 2, and 3 minutes. At the end of the time interval, the propane torch is removed. A can is placed over the sample, and then cooled to room temperature.

Indirect Heat Method

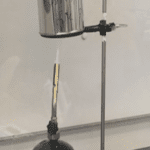

Substrates are placed onto an upside down can lid, which is positioned on a ring stand with the substrate surface most commonly exposed to a heat source, facing downward. For example, a carpet sample is positioned so the tufted or woven textile side is in contact with the can lid. The torch flame is applied at a 75 degree angle underneath the lid. The time interval begins once smoke appears. A sample is prepared for each of the three time intervals: 1, 2, and 3 minutes. At the end of the time interval, the propane torch is removed. A can is placed over the sample, and then cooled to room temperature.

Interfering products from the heated and unheated (unburned) substrate materials are collected by passive headspace adsorption onto activated carbon following ASTM E1412 standard method. An activated carbon strip (10mm X 22mm) is suspended into the headspace of the scan by a paperclip and un-waxed dental floss. The sealed can is heated for 16-18 hours at 66 degrees Celsius.

MRN 1 – 216: the activated carbon strip was removed from the can, cut in half and placed into a vial with 0.50 milliliters of carbon disulfide.

MRN 220 – : the activated carbon strip is removed from the can and placed into a vial with 0.50 milliliters of carbon disulfide.

Instrument Parameters

Instrument and Accessories

Prior to 2014

Agilent 6890 gas chromatograph and 5973 mass spectrometer

2014 to present

Agilent 7890 gas chromatograph and 5977E mass spectrometer

Agilent ALS autosampler

GC Conditions

Column: HP-1 or equivalent

Length: 25 meters

Inner diameter: 0.20 millimeters

Film thickness: 0.5 microns

Carrier gas: helium (ultra high purity)

Flow: constant

Flow rate: 0.8 ml/min

Linear velocity: approximately 36 cm/sec

Split ratio: 50:1

Injection volume: 1 microliter

Pre-injection washes of sample: 2

Pumps: 2

Post-injection wash of solvent A: 10

Post-injection wash of solvent B: 10

Plunger speed: fast

Injection temperature: 250 degrees Celsius

Initial oven temperature: 50 degrees Celsius

Initial hold time: 3 min

Rate: 10 degrees Celsius per minute

Final temperature: 280 degrees Celsius

Final hold time: 4 min

Total run time: 30 min

MS Conditions

Transfer line temperature: 280 degrees Celsius

Acquisition mode: scan

Scan range: 30-350

Scan rate: 2-3 scans/sec; equivalent to 6-10 scans per peak

Solvent delay: 2 min. As of November 2010, there is no solvent delay instead the detector is off between 1.54 and 2.00 minutes.